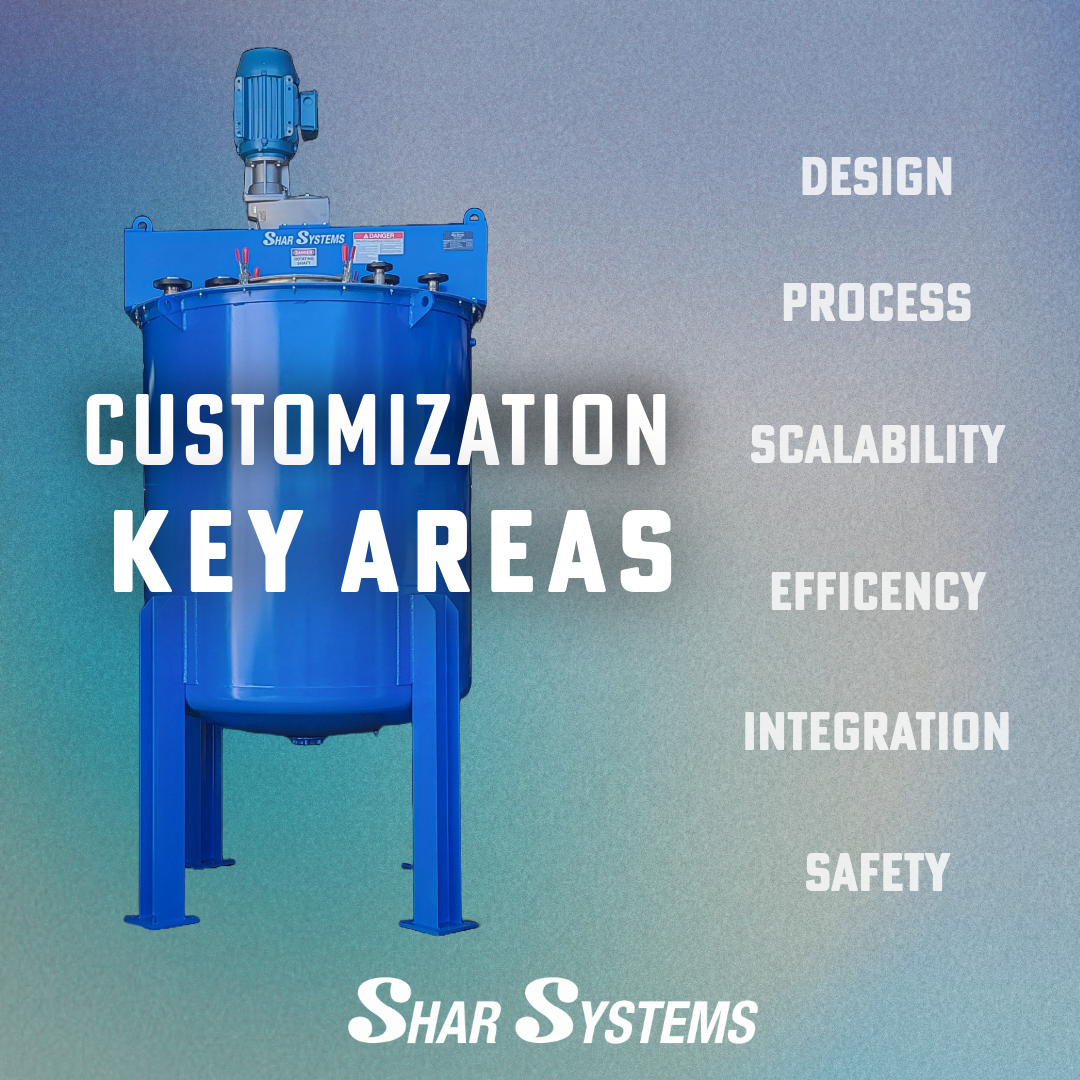

In our previous article, we discussed why customization matters in industrial mixing. Now, let's dive deeper into the key areas where customization can make a significant difference in your mixing processes.

Our commitment to American manufacturing allows us to maintain strict quality control throughout the customization process, ensuring excellence in each of the following key areas:

1. Mixing Equipment Design

The design of mixing equipment is crucial to process efficiency. Customization here can include:

- Tank geometry and size

- Impeller type, size, and configuration

- Materials of construction for different chemical compatibilities

2. Process Control Systems

Advanced control systems allow for precise management of the mixing process:

- Automated recipe management

- Real-time monitoring and adjustment of mixing parameters

- Control of blend, temperature, mix speed, and time

3. Scalability

Customized solutions can be designed to accommodate varying production needs:

- Flexible batch sizes to accommodate a wide range of production requirements

- Modular designs that allow for easy scaling of production capacity

4. Energy Efficiency

Tailored mixing solutions can significantly reduce energy consumption:

- Optimized motor sizes and types for specific applications

- Implementation of energy-efficient mixing techniques

5. Integration with Existing Systems

Custom mixing solutions can be designed to seamlessly integrate with:

- Existing production lines

- Material handling systems

- Quality control processes

- Broader manufacturing execution systems

6. Safety Integration

Modern mixing solutions prioritize operator and process safety through:

- Tank-in-place sensors for secure operation

- Machine guards to protect operators

- Emergency stop systems

- Safety interlocks and alarms

- Automated safety protocols

- Compliance with industry safety standards

By focusing on these key areas of customization, manufacturers can significantly enhance their mixing processes, improving efficiency, product quality, and overall competitiveness.

At Shar Systems, we specialize in creating American-made, customized mixing solutions that address each area. Our team of experts works closely with you to understand your unique needs and develop a solution that optimizes your specific mixing processes.

Ready to explore how customization in these key areas can transform your production process? Contact Shar Systems today. Let's work together to create a mixing solution perfectly tailored to your needs.