Every product, every material, and every production line has unique requirements. Standard, off-the-shelf mixing equipment often falls short of meeting these specific needs, leading to:

- Inefficiencies in production

- Inconsistencies in product quality

- Increased waste and energy consumption

- Limitations in scaling production

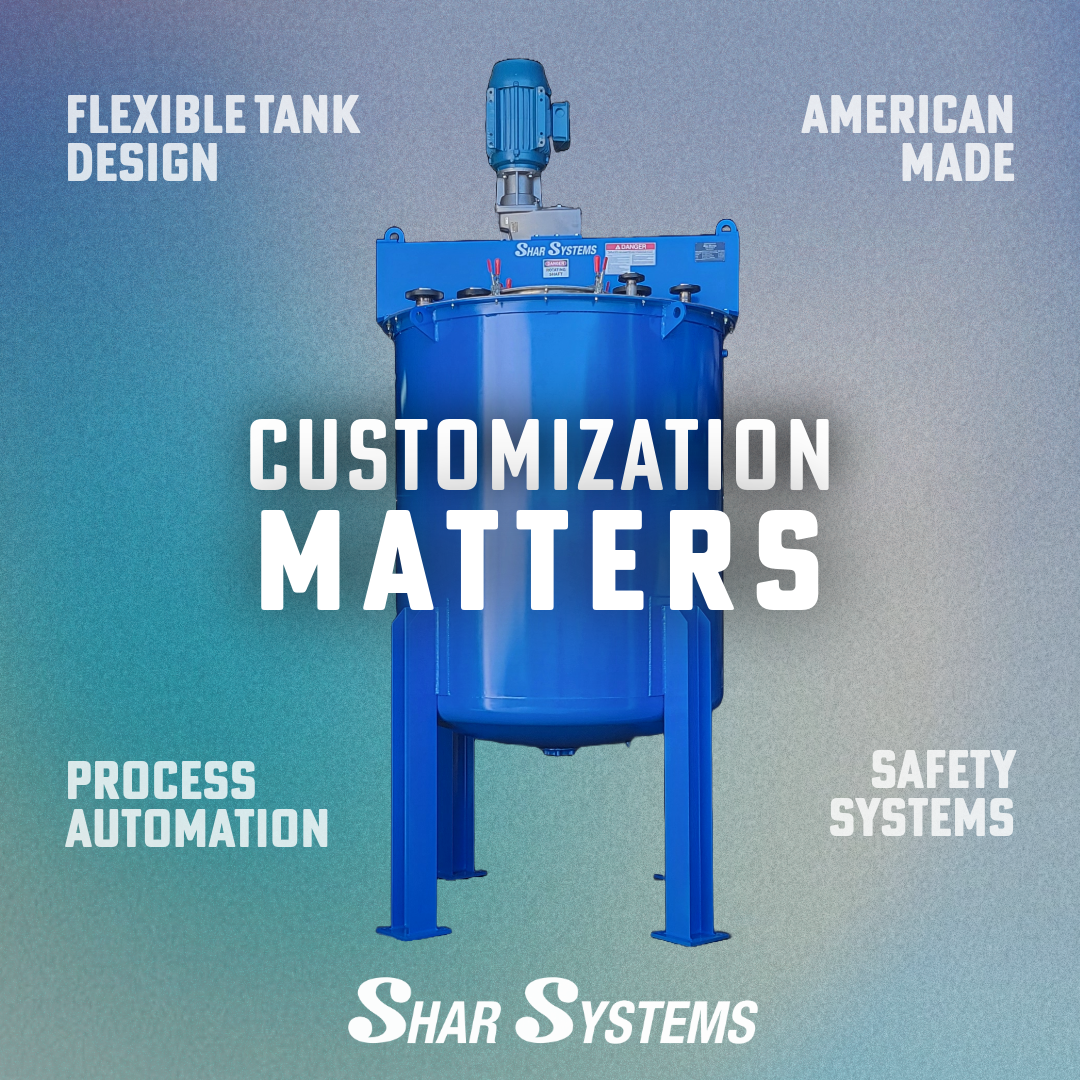

Customization allows manufacturers to overcome these challenges by tailoring their mixing processes to their exact specifications. At Shar Systems, we pride ourselves on providing American-made, customized solutions that address these challenges head-on.

The Impact of Customization

While every manufacturing process is unique, customization in industrial mixing processes can lead to significant improvements:

- Reduced labor costs through automation

- Increased consistency in product quality

- Enhanced safety through modern features like tank-in-place sensors, machine guards, and emergency stops

- Streamlined inventory management

- Shortened production cycles

- Improved energy efficiency

These benefits can translate into substantial cost savings and improved product quality, giving manufacturers a competitive edge in their respective markets.

In today's competitive manufacturing landscape, the ability to fine-tune processes can make all the difference. Customized mixing solutions offer a powerful way to optimize production, improve product quality, and stay ahead of the competition.

At Shar Systems, we're committed to providing tailored mixing solutions that address the unique challenges of each customer. Whether you're dealing with challenging materials, striving for greater efficiency, or pushing the boundaries of product innovation, a customized mixing solution could be the key to unlocking your manufacturing potential.

We invite you to reach out and discuss how these customization opportunities can be applied to your specific mixing challenges. With our decades of experience and commitment to innovation, we're ready to help you optimize your mixing processes — exactly the way you need.